In this month, we began looking into the finalization of the portable + foldable mounting ramp and began preparations for the conceptualization, selection, and purchasing of the remaining components—which includes the hand-rails, expanded metal flooring, hinges, and (a new item) the flooring extension. To ensure a clear understanding of the project, we met with the project partner, Bobby Valdez, and Andrew Bitner to discuss the details, complications, and feasibility of certain components.

In our first meeting with Bobby Valdez, we discussed the initial state of the project and the major goals for this semester. Here, we learned that the frame, designed by previous teams, had already been fully manufactured and welded together, leaving the finishing touches (e.g., the flooring, handrails, hinges) for our team to complete. Bobby mentioned including additional features for the frame such as extending the flooring over the wheels and implementing side-covering panels to prevent the horses from getting injured by kicking the wheels or by having limbs get stuck in the frame, respectively. However, as implied by Andrew Bitner, these additions may not be feasible for the scope of this semester since the costs for the project had already gone over budget in the previous semester.

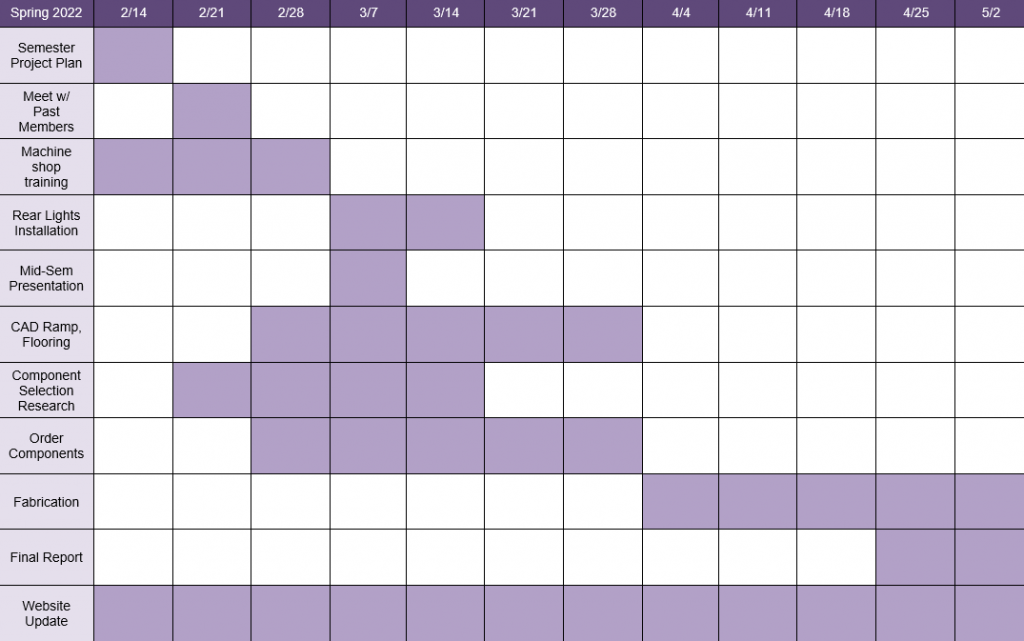

A few weeks into February, our team further organized this semester’s goals with the completion of our Project Charter and Project Plan. Here, we highlighted our main tasks and produced a Gantt chart timeline for us to keep track of time.

Since then, we’ve started looking into the conceptualization of this semester’s additions. As mentioned earlier, we met with Andrew Bitner to discuss these concept topics and, subsequently, we were left with a general understanding of how we could approach these various components. Starting off with the handrails, we decided that they would be inserted into sockets on the side of the frame and be removable—allowing users to easily detach the rails and, thus, be able to fold the ramp when needed. However, for the component itself, we could either design the rails ourselves or look into potential online options to save cost and time. For the flooring, the previous semester had already ordered the necessary amounts of expanded metal for the completed frame, though additional material may be required to satisfy the added dimensions from an included flooring extension (which is discussed later). The previous semester introduced piano hinges as a potential option for the ramp hinge, which spans the width of the ramp. To save cost, we are looking into other options of smaller sizes that we can use in numbers to attach the frame components. However, the derivation of force ratings for these other options becomes necessary to ensure zero mechanical failure can occur. These derivations will depend on how we attach the hinges to the frame (either bolts or fillet welds). Finally, we conceptualized how we could approach the platform extension which covers the outward protrusion of the trailer’s wheel and fender. The likelihood of implementing this depends on the budget we’re provided for this semester.

For next month, our plan is to:

1. Complete the selection/design of the components (Before Spring Break)

2. Purchase the necessary material and components (Before and After Spring Break)

3. Begin machining/welding at the UTD Machine Shop and assist Andrew (After we complete the machine shop training)