During November, some of our team members felt that due to health concerns, it was best that they no longer visited the UTDesign Studio this semester. The progress we made this month was divided into two main goals: continued assembly of the trailer base, and logistics concerning the Portable Mounting Ramp.

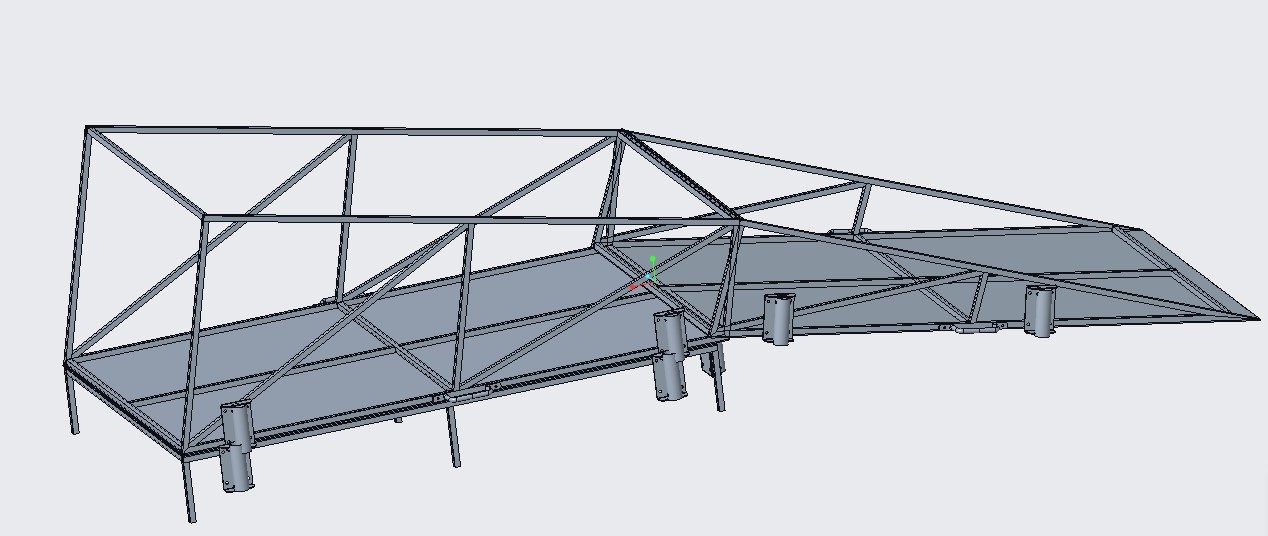

As it stands, we have completed approximately 90% of the trailer base. We are currently stumped while attempting to affix the wheels to the base, which is barring our progress. However, the main frame of the ramp is completed, and the pieces that come after the wheels are add-ons such as the handles.

The instructions mentioned removing the hub caps of the wheels so that we could slide the wheel onto the side of the trailer base, after which we would have to reapply the hub cap. However, this caused a roadblock, as there was some sort of blue lubricant within the bearing of the wheel that would ooze out was we applied pressure. Currently, we have not secured the wheels to the trailer base.

**We limited our time in close proximity to 15 minutes per day as specified in the UTDesign Studio safety requirements. We made sure to wear a face mask at ALL times, and applied a face shield BEFORE coming in close proximity for long durations.**

Our team members that stayed home worked on some of the logistics of the ramp. This included converting the ramp assembly into a CREO file from a SolidWorks file, continuing research into railing alternatives, and brainstorming alternatives for the ramp walking surface and side coverings. We also began taking part inventory using the updated CREO model in order to prepare a Bill of Materials for next semester’s procurement request.

Regarding the walking surface, one of our main considerations was replacing the solid 0.15″ thick steel plated with a thicker, meshed steel walking surface. This would cut the cost of the walking surface down, and we already had some of the material on hand to experiment with. In order to go through with this change, we must ensure that walking canes will not skip through the holes in the mesh and that the structural load-supporting capabilities of the mesh equal or exceed the requirements given to us by Equest.

Considering our limitations under current circumstances, we think this semester has been very productive for the Equest Portable Mounting Ramp project. We ironed out the design flaws in the ramp, completed the majority of the trailer base, and have a part inventory on the verge of completion. It has been a blast to work as a team on this project, and we hope the Portable Mounting Ramp will be finished next semester!