April was the month we finally made substantial physical progress on the ramp, along with organizing a logistical framework for the assembly process. Most of this month was geared towards completing the top platform of the ramp, learning from the process, and outlining a framework for the rest of the ramp assembly process.

Logistics

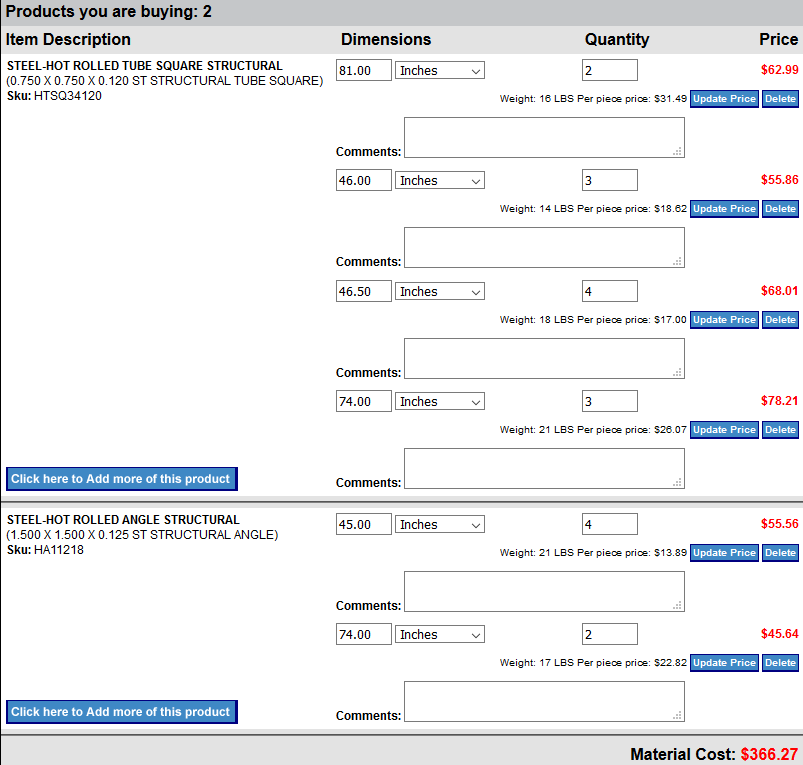

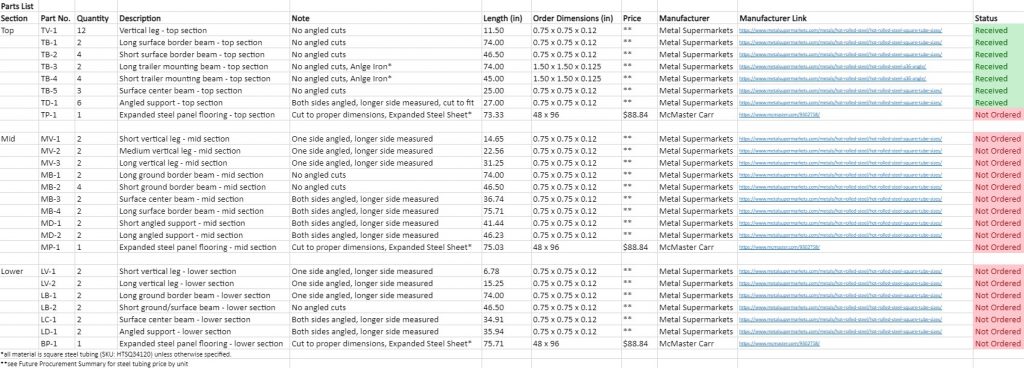

We began by contacting vendors from which to order our steel for the frame of the top platform and also contacting Andrew Bittner from the UTD Machine Shop to set up our in-person training and review our engineering drawings. We ended up choosing MetalSupermarkets as our vendor as they cut the steel to lengths we specified and delivered quickly and free of charge. We refrained from ordering the walking surface of the ramp, as our primary focus with this order was to complete the frame of the top platform and attach it to the trailer base.

Then, we created a Parts List to document all the core ramp frame parts needed for assembly. This included parts we already had, and parts that would need to be ordered in the future. We also developed a custom part number for each part, for organizational and labelling purposes.

The main reason we established the Parts List was so we could plan the future procurement of core ramp components weeks in advance and streamline the process. This will increase the time we have to work in the Machine Shop in the future assembly stages. Moreover, we also were able to obtain a rough estimate for the amount of money we would need for the rest of the core components of the ramp.

Assembly

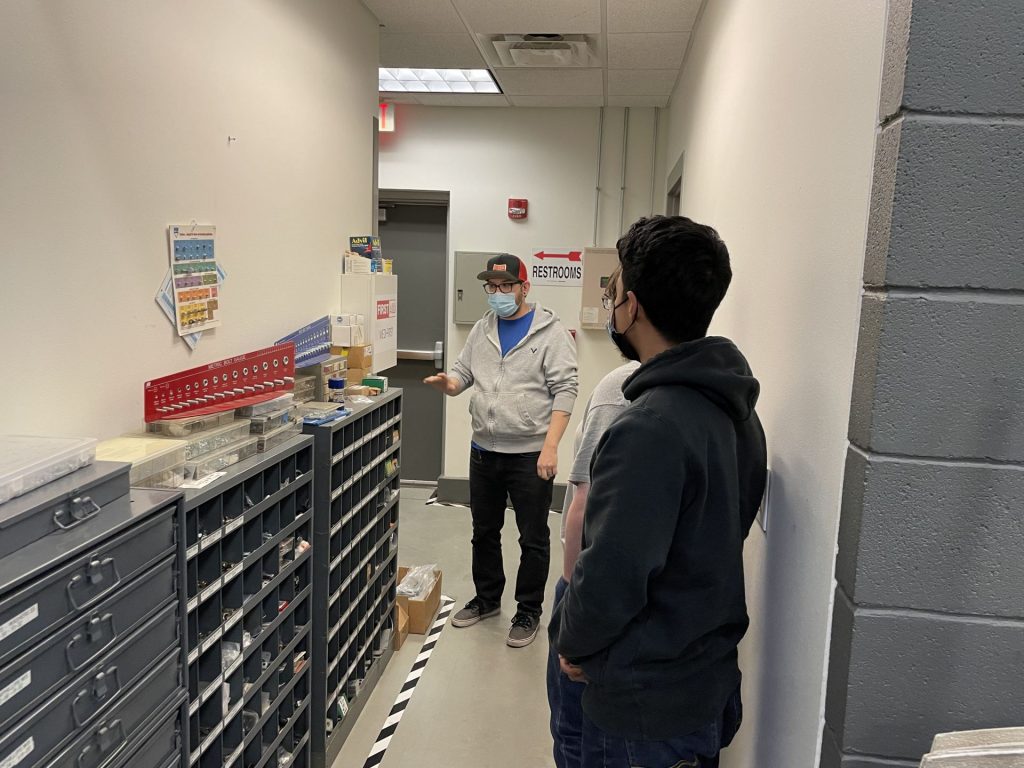

Our first experience in the UTD Machine Shop was a crash course on the machines we would be using for cutting and sanding the steel we ordered. Our main purpose in the machine shop was to prep the raw components for Andrew Bittner to weld and to provide detailed engineering drawings for him to use during assembly. But first, we needed to complete our training.

After our training, we moved the steel from the UTDesign Studio to the UTD Machine Shop and began cutting and sanding the components. After this, it was time to help Andrew Bittner weld the frame of the ramp together.

Future Design Considerations

While doing training in the UTD Machine Shop, we noticed another trailer from a senior design team parked in the machine shop. We also observed that the senior design trailer had a stabilization mechanism in place to hold the trailer steady while it was being loaded. We realized that our portable mounting ramp, being mounted on a trailer base with wheels, would also experience similar stability issues as that of the senior design trailer.

Our other upcoming design consideration is the railing solution. Although we created a price quote for the future core ramp components, we also made plans to add a permanent railing holder affixed to the ramp, meaning we would need to order more steel.

Upcoming Plans

For May, we will focus all of our efforts on preparing the raw materials for their final assembly during this semester. We will need to move the trailer base from the UTDesign Studio to the UTD Machine Shop, and we will need to order nuts, bolts, washers, and Rustoleum for the top ramp platform. Given the business and short length of our time on this project in May, it’s sure to be an exciting month.