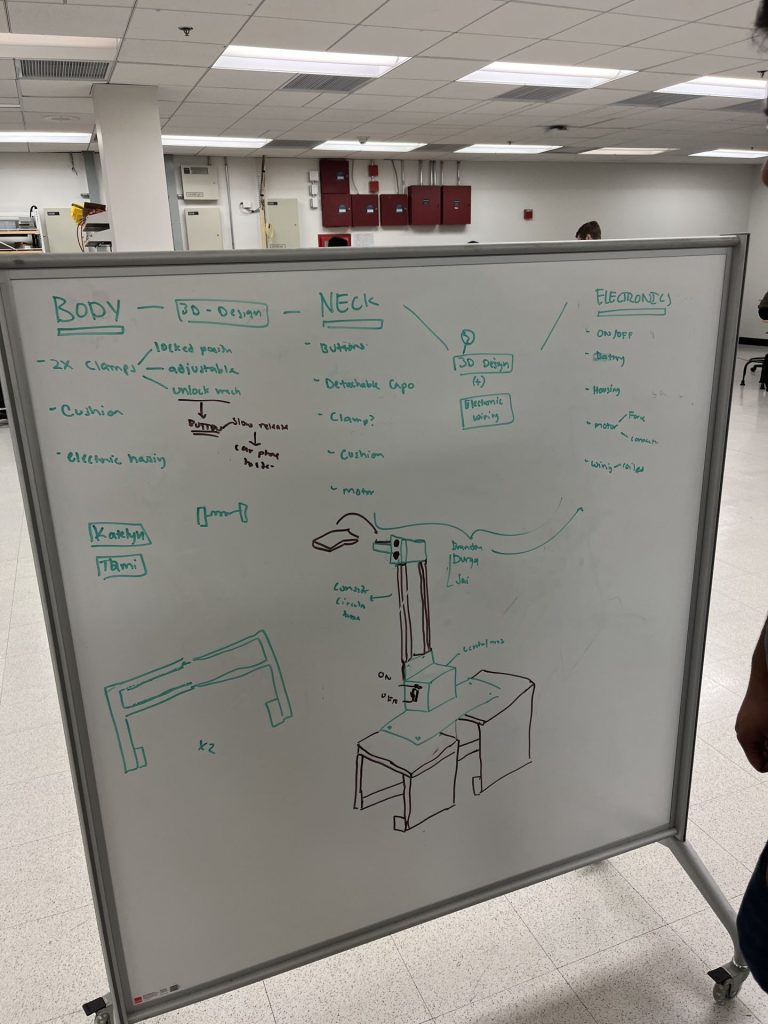

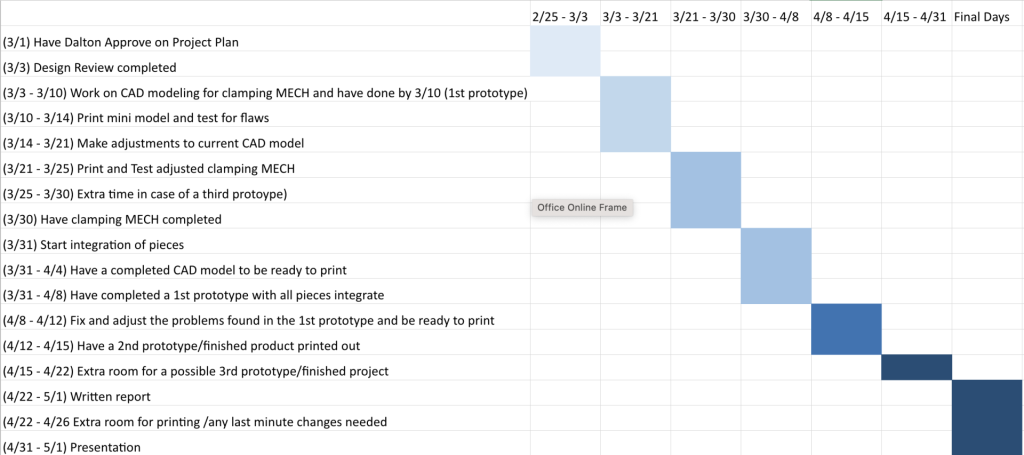

New Decisions and Additions to Design Process( Ideas )

Design Inputs

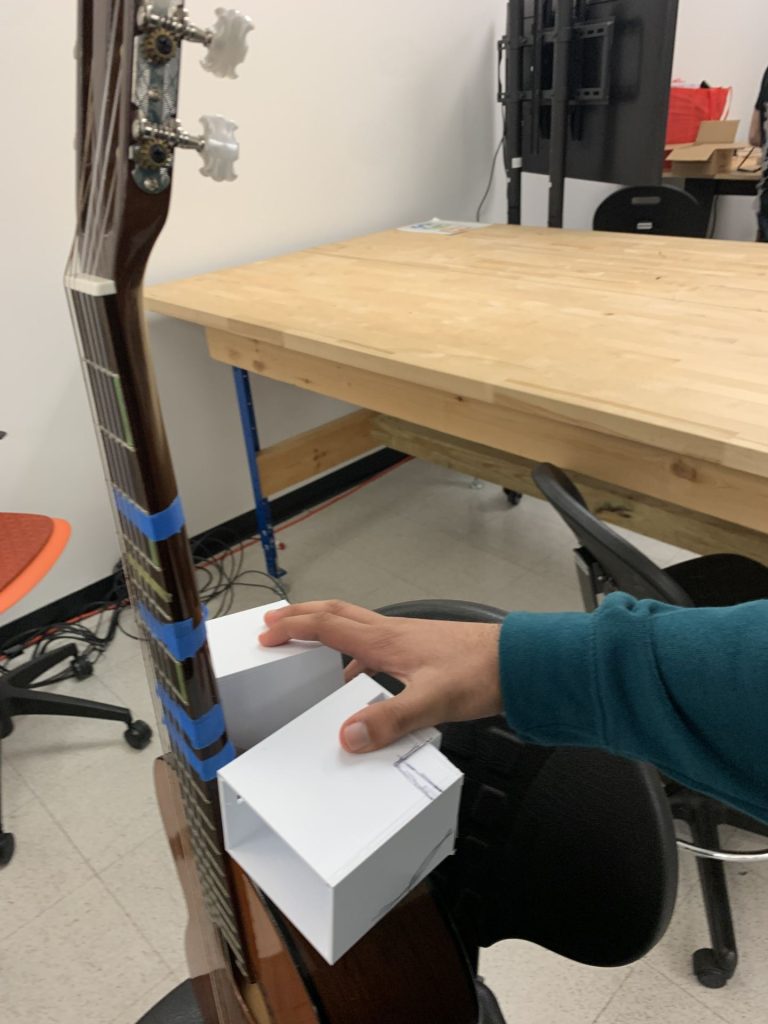

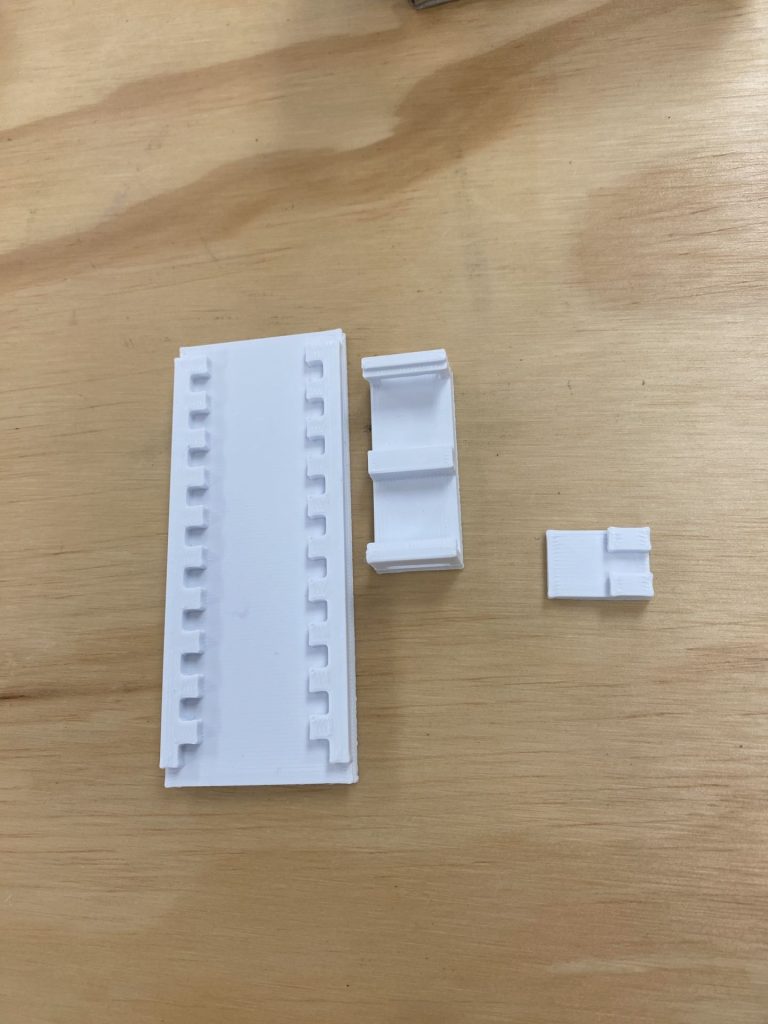

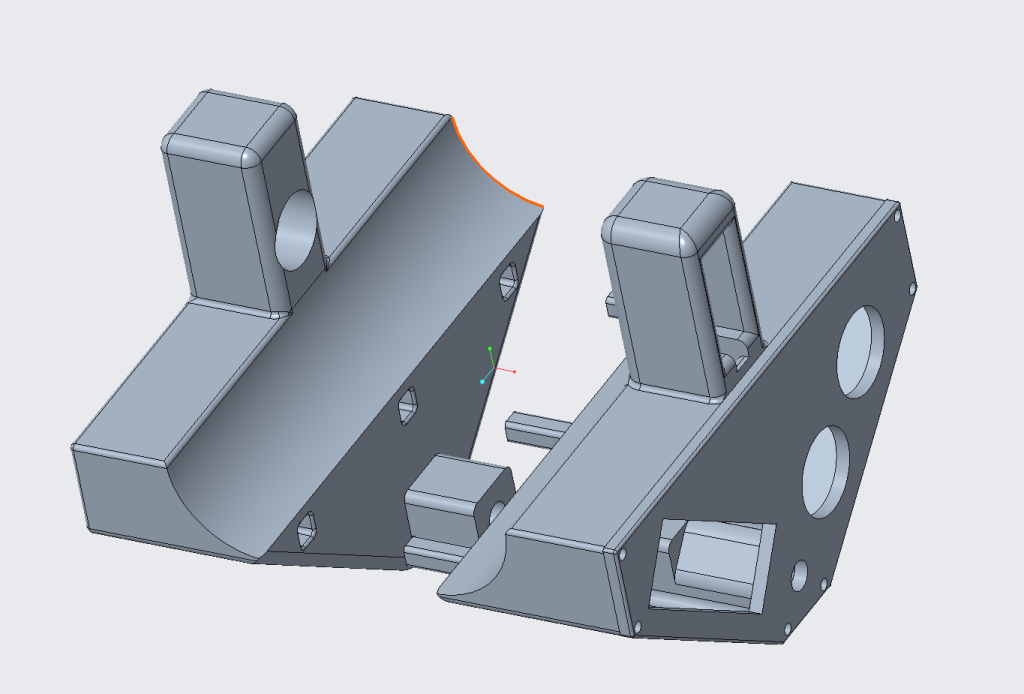

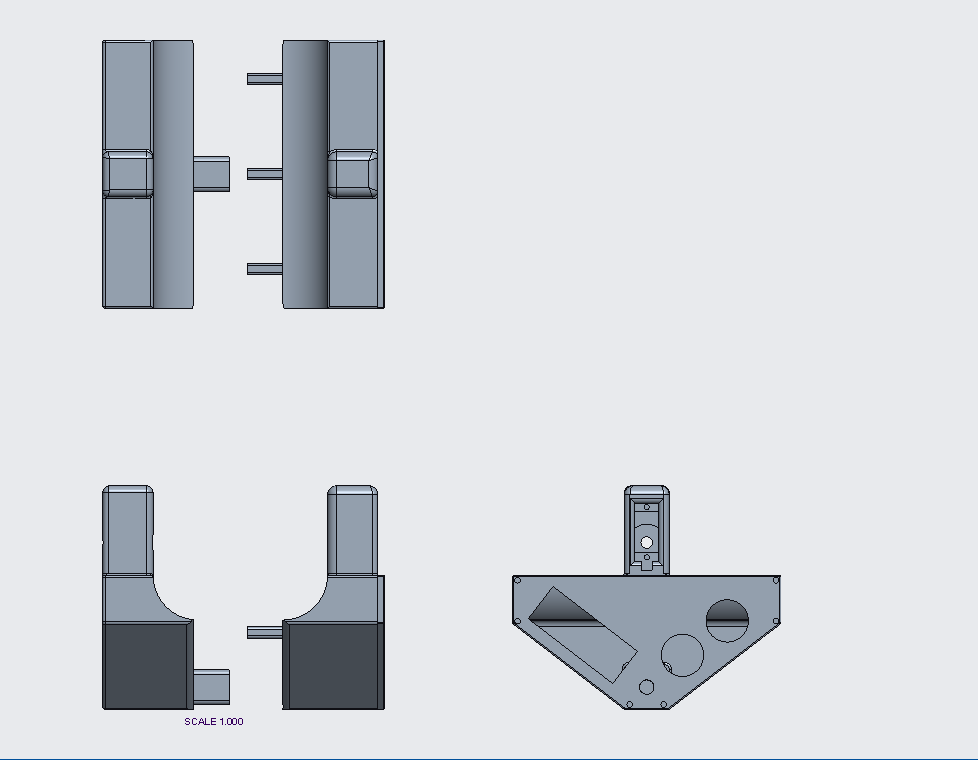

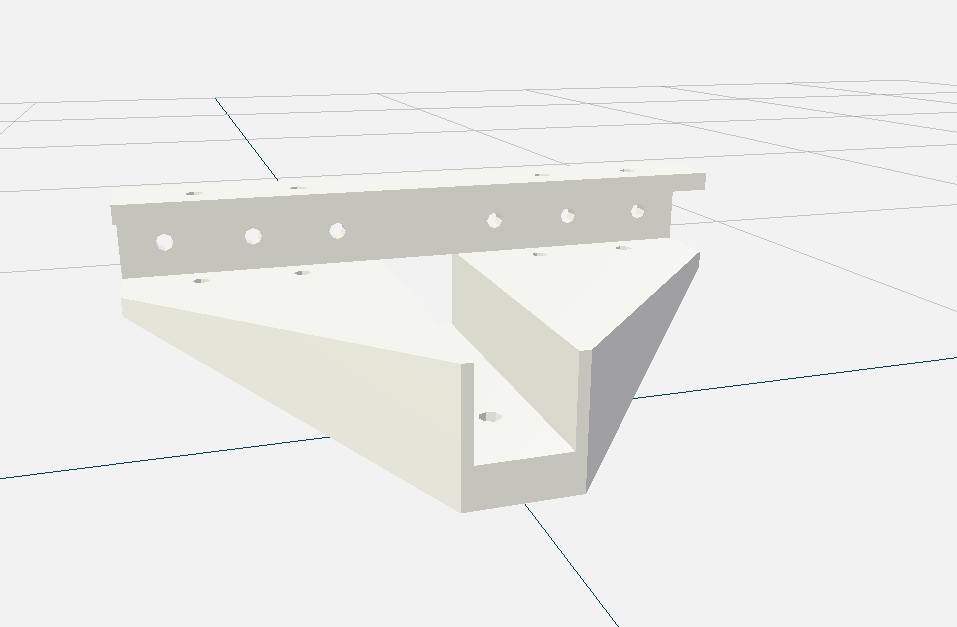

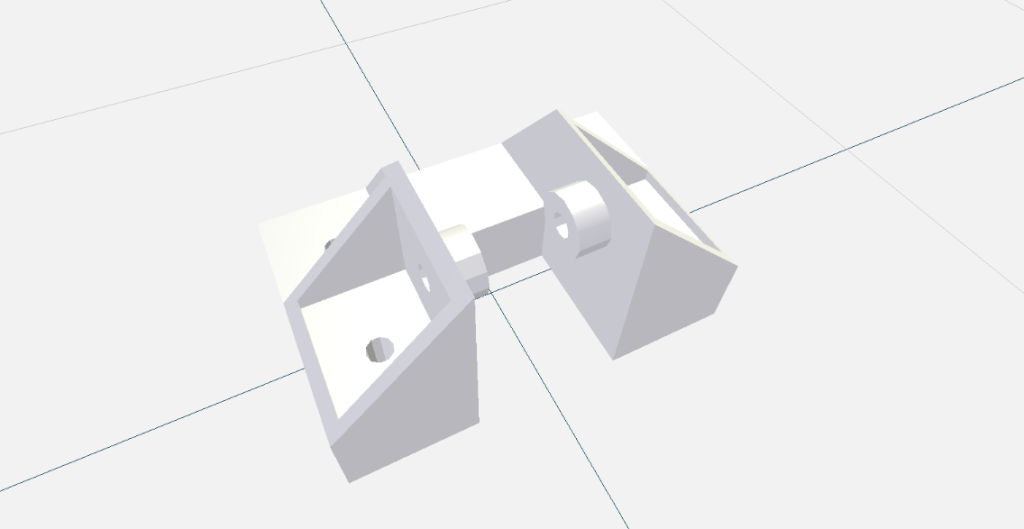

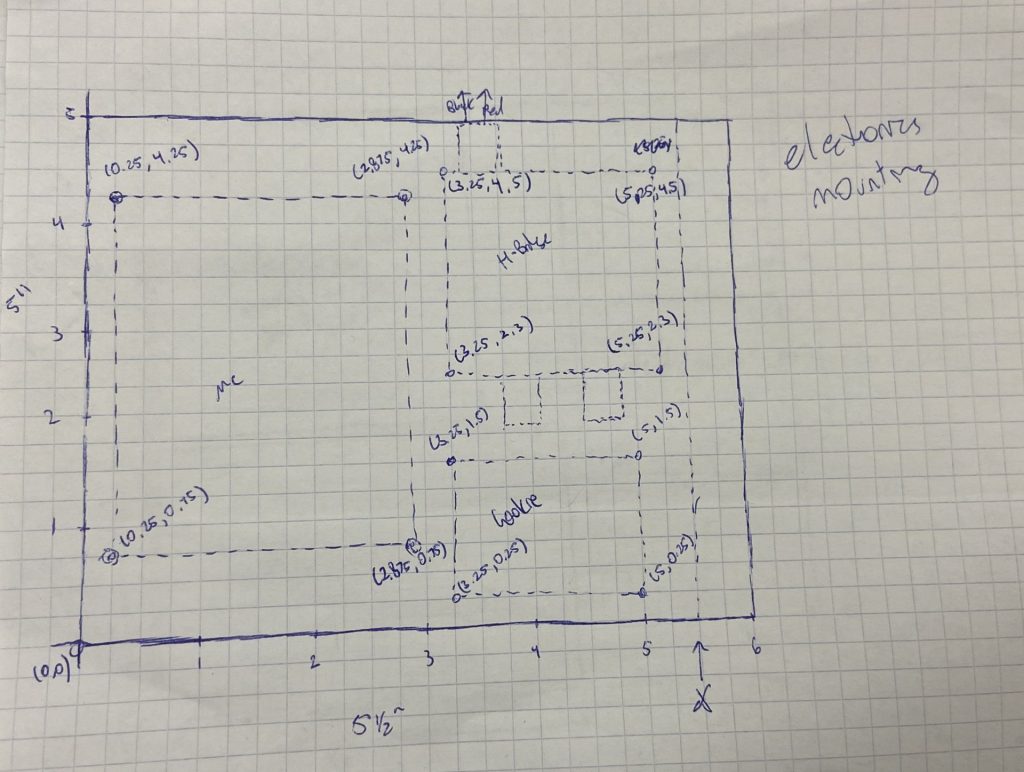

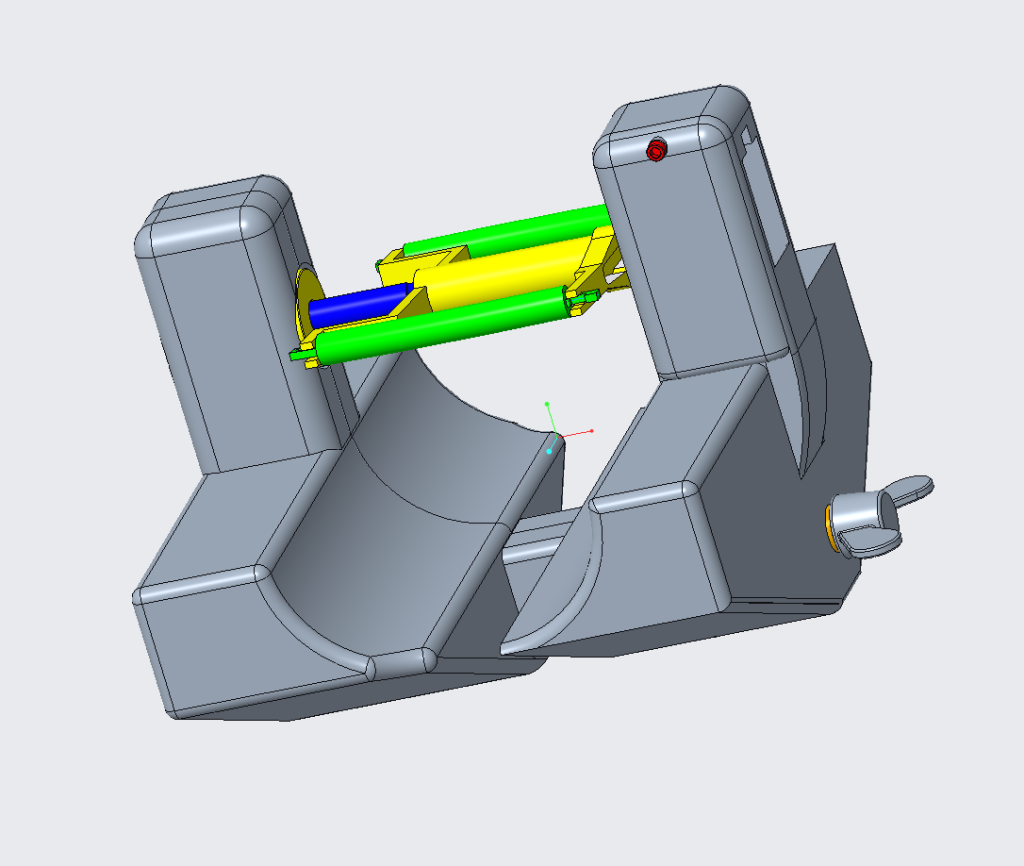

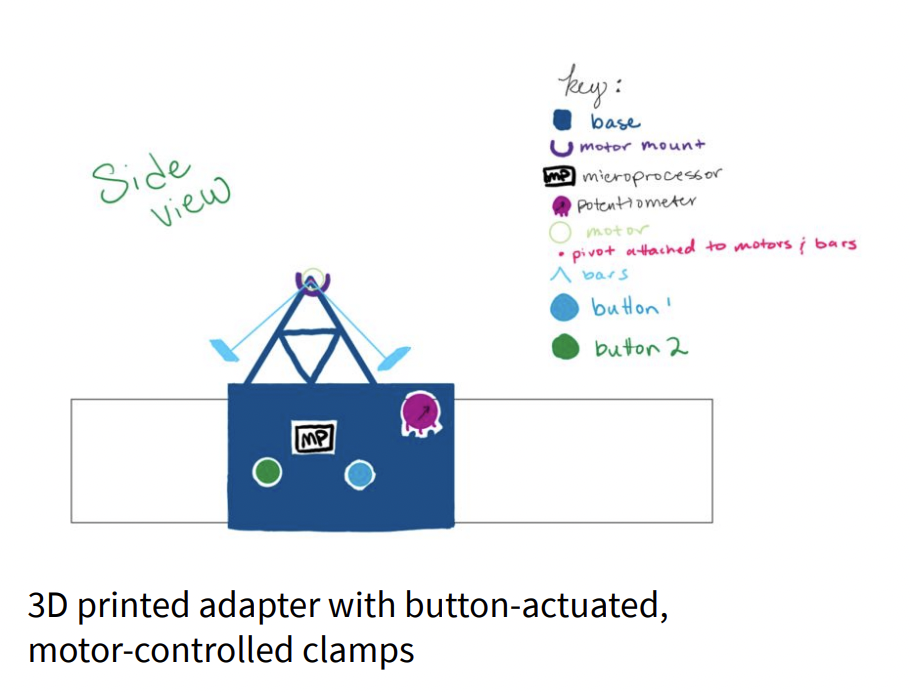

● 3D printed construction

● Motor-driven

● Foam contact material to depress strings

● Ergonomics and controls of adapter

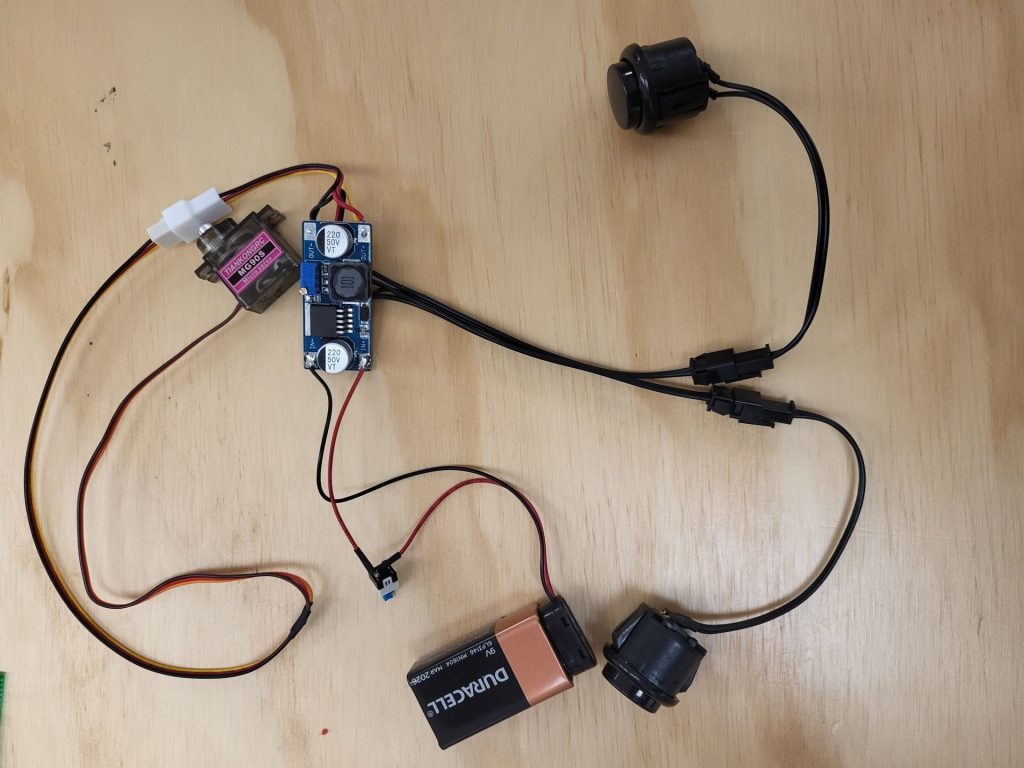

● Arduino

● Power source

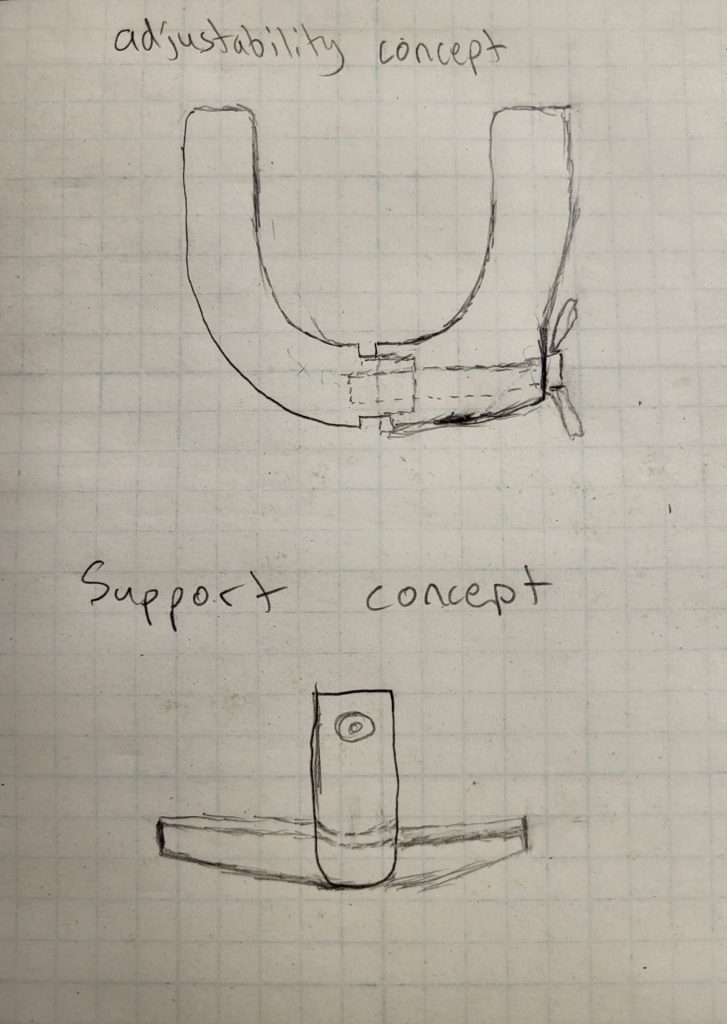

Brainstorming Session Outcomes; brought about several designs and methods of actuation. The following were proposed in light of the progressional design:-

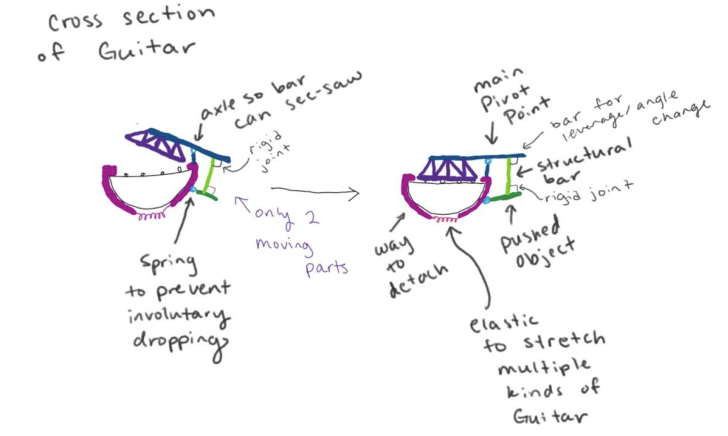

Mechanical actuation via springs and levers

○ Deemed inefficient due to complexity

and difficulty of use.

The use of guitar fret wire to lay across the strings

to “fret” the strings and the 5th and 7th frets.

○ Deemed ineffective due to the precision needed

to calibrate the mechanism and lack of consistent

sound when used.

The Current design being implemented for practicality will be unveiled in a future update post.